Conveyor Specialist aim to provide quality motors and gearboxes from well-known established brands to all our customers that meet every requirements.

We specialize in the sales and repairs of electric motors and gearboxes, suitable for conveyors, fans, gear reducers, pumps, food & beverage processing and other applications. All motors are available in different HP ratings, speed ratings and voltage ratings.

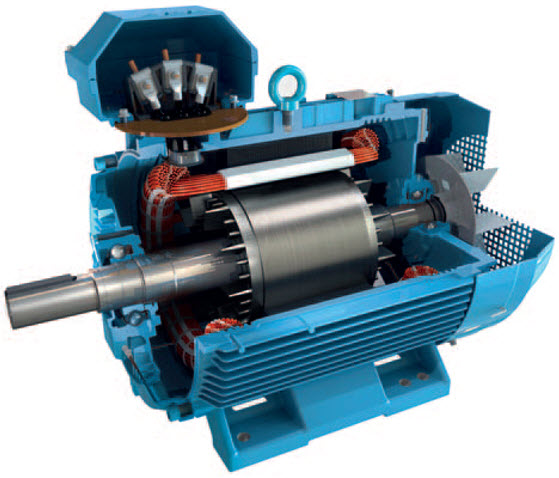

Three-Phase Motors

Three-phase motors (also annotated numerically as 3-phase motors) are widely used in industry and have become the workhorse of many mechanical en electromechanical systems, because of their relative simplicity, proven reliability and long service life.

Three-phase motors are a type of AC motor that is a specific example of a polyphase motor. These motors can be either an induction motor (also called an asynchronous motor) or a synchronous motor. The motors consist of three main components – the strator, the rotor and the enclosure.

Some of the advantages like low cost, rugged design less complex and easy to maintain AC motors result in many of the industrial operations are performed with the use of AC drives than DC drives. AC induction motor is a special type of electric motor, having its own typical characertistics and performance in terms of starting, speed control, protections and so on.

Thus the three phase induction motor is self-starting, less armature reaction and brush sparking, because of the absence of commutators and brushes that may cause sparks, robust in construction economical and easier to maintain.

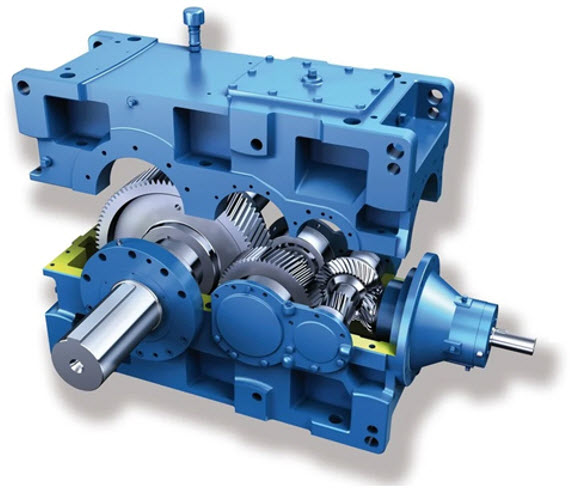

Industrial Gearboxes

An industrial gearbox is a system in which the mechanical energy is transfered from one device to another and is used to increase torque, while reducing speed. Gearboxes can modify their speed, torque to convert energy into a compatible format. They are useful in easing out the mechanical functioning in industries.

Helical gearboxes, coaxial helical line, bevel helical gearboxes, skew bevel helical gearboxes, worn reduction gearboxes, planetary gearboxes are some of the standard gearboxes used in industries.

Helical Gearbox

The helical gearbox is compact and a low-powered consumer. This equipment is used for a broad range of industrial applications, but typically in heavy-duty operations. The helical gearbox is popular in the construction of plastics, cement, rubber and other heavy industrial settings. It is useful in crushers, extruders, coolers and conveyors, which are all low-poer applications.

Coaxial Helical Inline Gearbox

The coaxial helical gearbox is ideal for heavy-duty applications. Coaxial helical in lines are noted for their quality and efficiency. The bevel helical gearbox is used to provide rotary motions between non-parallel shafts. These are typically used in quarries, in mining industry and conveyors.

Skew Bevel Helical Gearbox

The skew bevel helical gearbox is notable for its rigid and monolithic structure, which makes it usable in heavy loads and other applications. These industrial gearboxes offer mechanical advantages once they are mounted on the correct motor shaft output. These are customizable based on the number of teeth and gears. Therefore, you can usually find one suitable for your needs.

Worn Reduction Gearboxes

Worn reduction gearboxes are used to drive heavy-duty operations.These gearboxes are used when there is a need for increased speed reduction between non-intersecting crossed axis shafts. Most of these industrial gearboxes are used in heavy industries, such as fertilizers, chemicals and minerals.

Gear Unit

A gear unit is required to convert the roque and speed of an upstream electric motor, so that they meet the technical drive requirements of an application. For that reason, the gear unit is the central component of a gear motor.

A gear unit transforms the speed of a motor into steps up or steps down. The resulting speed ratio in between the input speed and output speed is therefore one of the most important characteristic values of a gear unit.

Gear units are distinguished by the type of force flow that they transmit. As a result, there are three basic designs: Parallel-shaft gear units, right-angle gear units and planetary gear units.

Parallel-shaft Gear Unit

Parallel-shaft gear units and planerary gear units, the input and output shaft are positioned in one direction (on the same level). The power is therfore transmitted in a straight line. Parallel-shaft gear units are available in a helical gear unit or parallel-shaft helical gear unit mounting position.

Planetary Gear Unit

Planatary gear units are a special form. With them, the power transmission is coaxial. The input shaft and output shaft move in the same direction throughout this preocess. In combination with a servomotor planatary servo gearmotors provide particularly high dynamics and precision.

In right-angle gear unit, in contrast, the drive shaft and output shaft are perpendicular to each other. There are three established versions of right-angle gear units. They include helical-bevel gear units, helical-worn gear units and right-angle gear units.