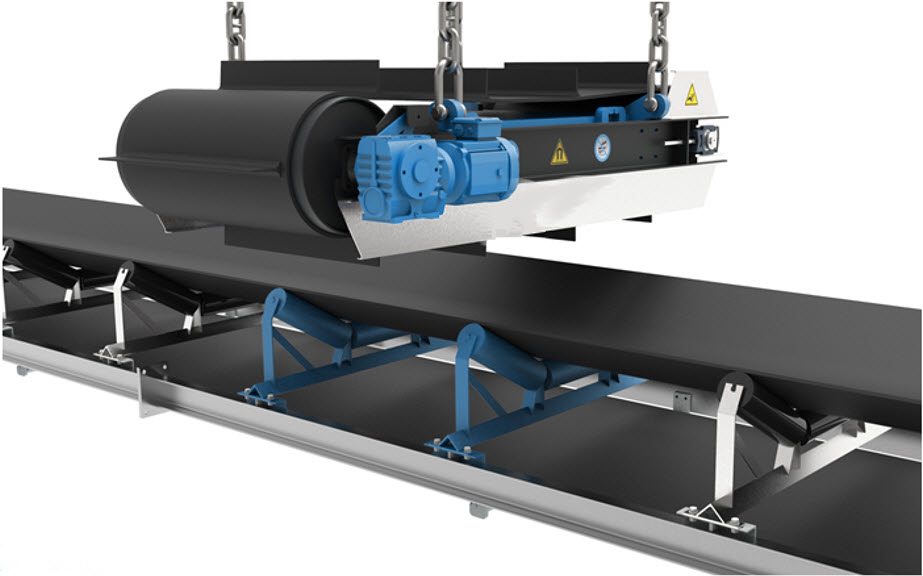

Permanent crossbelt magnetic seperators are a cost effective solution for a wide range of industries. Conveyor Specialist’s line of permanent crossbelt magnetic seperators was designed to meet the unique needs of recycling and quarrying solutions.

This lightweight magnetic seperators has extremely low running costs, as the permanent magnet requires no power source in order for the magnet to operate. Its self-cleaning design reduces downtime to a minimum, significantly increasing efficiency in your facility. All models are designed to be virtually maintenance free, saving you the expense of lost production time.

Conveyor Specialist’s permanent crossbelt magnetic seperator is excellent for applications that require a magnet to seperate at up to 550mm above a conveyor. These seperators are available in standard models, suitable for operation over 300mm to 1800mm conveyor belts and offers extensive custom design options to suit larger conveyor belt widths. Additional support structures are also available.

Typical applications for the use of Permanent Suspension Magnets include removal of iron from coal, stone, fertilizers, recycled asphalt, ores and similar materials where contamination by tramp iron is occational. These overhead magnets can be mounted either horizontal or inclined over the head pulley. All stationary magnets are fitted with a set of adjustable suspension chains, designed to suit application and attach to suspension lugs. Prefered installation position is above the head pulley, where the burden is spread out and the material is in virtual suspension as it is discharged from the conveyor.

Over Band Conveyors can be mounted on a variety of structures, including runway beams (using a trolley for suspension and movement) or A-Frame structures.

Two most common types of installations

Typically crossbelt magnets are suspended by their eyebolts over the conveyor at a specific distance known as the “working gap”. The “working gap” is the distance from the magnet face to the bottom of the material being processed.

Normal suspension options include being suspended from a goal post, A-Frame or 4-poster type steel structure. These options are available for both crossbelt (perpendicular to the conveyor processing the material) and in-line applications (samedirection as the conveyor and over the head pulley). When tramp ferrous materials pass underneath the magnet, they become attracted to the face of the magnet. Then, the cleated belt moves the metals clear of the conveyor burden, transports it out of the magnetic field and discharges it away from the conveyor.

Benefits of Self-Cleaning Crossbelt Magnetic Seperators:

- Overall low operating costs keep your facility moving and your budget in check.

- Self-cleaning mechanism minimizes downtime and greatly improves operational efficiency.

- Designed to be virtually maintenance free, reducing costs, downtime and stress.

- Advanced safety features protect your employees as well as the equipment in your facility.

- Equipment can be custom designed to suit almost any application, including yours.

- Versatile mounting options facilitate ease of installation.