Pulley reconditioning or refurbishing is recommended when the shell and the shaft of the pulley is still in good condition. If the lagging, bearings, or locking assembly are worn, a reconditioning job will save you the costs of a complete pulley replacement.

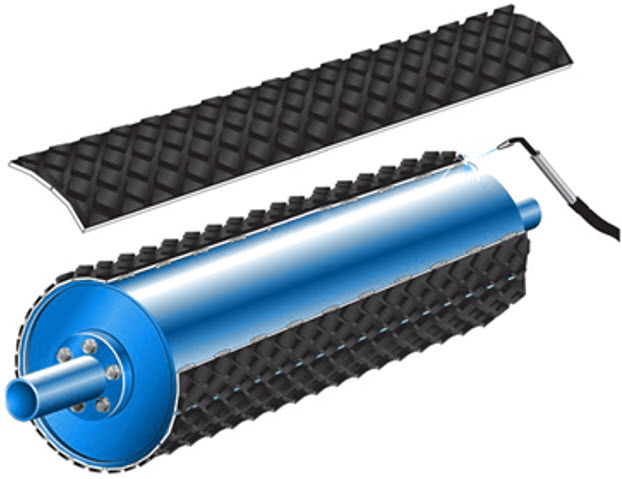

Pulley reconditioning (or refurbishing) is the process of extending the life of an old pulley. This process involves the smoothing down of the pulley shell so that new lagging can be applied. The shell and shaft of the pulley undergoes specialized and rigorous testing to determine whether they are still in working condition or need to be replaced. Replacement lagging will ensure the pulley shell is protected and the conveyor belt traction is maintained. Pulley re-lagging involves removing the old lagging material and replacing it with a new layer. A brand new bearing and locking assembly can be fitted to replace the old set. Finally, a pulley may be spray-painted or coated to replicate its original aesthetics. This can also protect the overlying metal from rust and corrosion.